Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

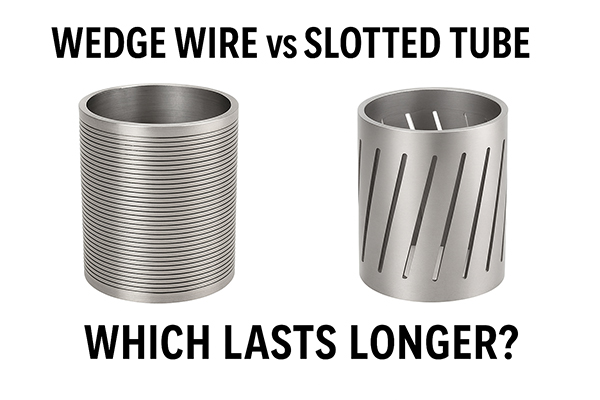

In real-world testing and industrial applications, wedge wire screens last 2–3 times longer than slotted tube filters in harsh environments. The difference lies in structure, stress resistance, and cleaning behavior.

| Feature | Wedge Wire Screen | Slotted Tube |

|---|---|---|

| Service Life | 6–8 years average | 2–4 years average |

| Wear Resistance | Excellent (V-profile reduces abrasion) | Moderate (flat edges wear quickly) |

| Clogging Tendency | Low | High |

| Corrosion Resistance | High (316L, Duplex steel) | Medium (often 304 or mild steel) |

| Maintenance Frequency | Once every 3–6 months | Monthly or more |

| Backwash Efficiency | 95%+ | 60–70% |

| Overall Durability | Superior | Limited by abrasive flow |

Wedge wire screens are the preferred choice for harsh, abrasive, or corrosive operations where uptime and efficiency matter. They outlast slotted tubes by a factor of two or more in real conditions.

A. Structural Strength

Wedge wire screens are welded from V-shaped profile wires on support rods. This design distributes stress evenly and resists deformation under load.

Slotted tubes, cut from solid pipe, concentrate stress around slot edges, causing microcracks and fatigue.

Test result (Mining slurry simulation):

Wedge wire retained 92% of open area after 5,000 hours.

The slotted tube dropped to 74% due to slot deformation and fouling.

B. Anti-Clogging Geometry

The self-cleaning V-profile of wedge wire allows solids to slide off during operation and backwashing.

Slotted tubes trap particles at sharp slot edges, requiring manual or chemical cleaning that shortens lifespan.

C. Material Advantage

Johnson Wedge Wire screens typically use SS316L or duplex steel, offering superior corrosion resistance in saline and acidic media.

Slotted tubes often use 304 stainless steel, which is more affordable but less resistant to pitting and crevice corrosion.

3. Cost Efficiency Over Time

Even if a wedge wire screen costs 20–30% more initially, its total lifecycle cost is significantly lower.

| Parameter | Wedge Wire | Slotted Tube |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Cost | Low | High |

| Downtime Loss | Minimal | Frequent |

| Cost per Year (Avg.) | ↓ 35–40% lower overall | ↑ Higher due to replacement cycle |

Over 5 years, a wedge wire installation saves up to 40% in total operating costs.

4. Best Applications

| Industry | Recommended Solution | Reason |

|---|---|---|

| Mining & Coal Dewatering | Wedge Wire Basket | Withstands abrasion and heavy solids |

| Wastewater Filtration | Wedge Wire Screen Panel | Resists fouling, easy backwash |

| Food & Beverage | Wedge Wire Cylinder | Hygienic and corrosion-resistant |

| Seawater Intake | Coanda Wedge Wire Screen | Handles high flow and saline corrosion |

5. The Engineering Perspective

If your system handles abrasive slurries, variable pH, or continuous operation, the wedge wire design is unequivocally superior.

It offers longer lifespan, stable flow performance, and fewer maintenance shutdowns - key metrics that determine ROI for any filtration operation.

In harsh industrial environments, Wedge Wire Screens outperform and outlast Slotted Tubes in every measurable category — durability, efficiency, and lifecycle cost.

FAQ: Wedge Wire vs Slotted Tube

1. What is the main difference between a wedge wire screen and a slotted tube?

A wedge wire screen is made by welding V-shaped profile wires onto support rods, forming continuous slots that resist clogging and wear. A slotted tube is cut or drilled from a solid metal pipe. While simpler to manufacture, it has straight slots that wear faster and clog more easily under high solids or abrasive flow.

2. Which lasts longer in harsh industrial conditions?

Wedge wire screens generally last two to three times longer than slotted tubes. Their welded V-profile design evenly distributes stress, reduces abrasion, and withstands chemical corrosion better, making them ideal for mining, wastewater, and seawater applications.

3. Why do wedge wire screens resist clogging better?

The V-shaped wire profile creates a self-cleaning slot — solids slide off the surface rather than getting trapped. This design allows continuous flow, efficient backwashing, and longer operational uptime with minimal maintenance.

4. What materials are best for wedge wire screens?

For harsh or corrosive environments, 316L stainless steel and duplex stainless steel are most common. They offer superior resistance to pitting, crevice corrosion, and chemical attack compared to 304 or mild steel typically used in slotted tubes.

5. Are wedge wire screens worth the higher initial cost?

Yes. Although wedge wire screens may cost slightly more upfront, they reduce downtime and replacement frequency, saving up to 40% in total lifecycle cost over 5–8 years. Their extended service life and low maintenance make them more cost-effective in continuous operations.

6. In what industries are wedge wire screens most beneficial?

They are widely used in:

Mining and coal dewatering (abrasion resistance)

Wastewater and industrial filtration (anti-clogging)

Food and beverage processing (hygienic surfaces)

Seawater intake systems (corrosion resistance)

7. How can I select the right screen for my process?

Consider your flow rate, solid particle size, pressure, and media type. For harsh or continuous-duty applications, a wedge wire design is recommended. Johnson Wedge Wire engineers can assist with slot size selection, CAD drawings, and performance data before purchase.