Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

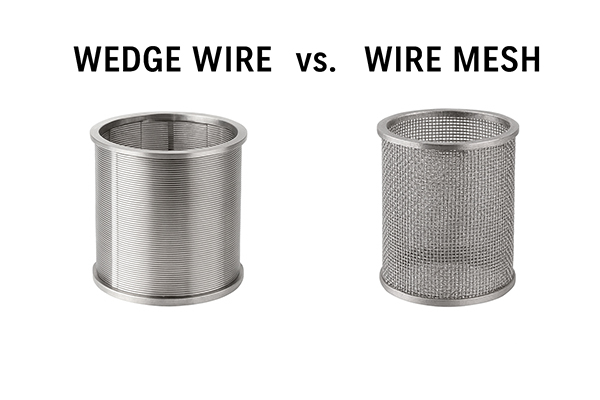

In industrial filtration, two materials dominate the conversation — Wedge Wire Screens and Conventional Wire Mesh Filters. Both play essential roles in removing solids from liquids or gases, yet their performance, cleaning ease, durability, and long-term cost differ significantly.

Understanding these differences enables engineers, maintenance teams, and plant managers to make more informed investments for long-term system efficiency.

1. Structure and Design: Why It Matters

Wedge wire screens are manufactured by welding V-shaped stainless steel wires onto support rods. This creates a continuous slot opening, ensuring consistent flow and non-clogging filtration.

In contrast, conventional wire mesh filters are woven structures made from intersecting metal wires. Although inexpensive and versatile, they often trap particles within their weave, leading to clogging and pressure loss.

In short:

Wedge Wire: Precision-engineered, self-cleaning slot design.

Wire Mesh: Traditional woven structure, more prone to blockage.

2. Cleaning and Maintenance Efficiency

Cleaning is one of the biggest operational challenges in filtration systems.

Wedge wire filters can be backwashed easily or cleaned with high-pressure water jets. Their smooth surface prevents particle adhesion, significantly reducing downtime.

Wire Mesh Filters, however, require manual brushing, chemical cleaning, or replacement, particularly when handling viscous fluids or sticky materials.

According to industrial case studies, wedge wire systems reduce cleaning time by 40–60% compared to wire mesh, enhancing process continuity and lowering maintenance costs.

3. Lifespan and Durability

Stainless steel wedge wire screens, especially those made from 304 or 316L stainless steel, offer superior resistance to corrosion, erosion, and mechanical stress. They typically last 5–10 years under continuous industrial operation.

By contrast, conventional wire mesh filters often deform or rupture under pressure, requiring frequent replacement—sometimes within months in abrasive or corrosive environments.

Data Summary:

| Filter Type | Typical Lifespan | Maintenance Frequency | Corrosion Resistance |

|---|---|---|---|

| Wedge Wire Screen | 5–10 years | Low | Excellent (316L) |

| Wire Mesh Filter | 0.5–2 years | High | Moderate |

4. Cost and Long-Term Value

While wedge wire screens involve a higher upfront cost, their long lifespan and reduced maintenance make them more economical in the long run.

Wire mesh filters are cheaper initially, but frequent replacements, cleaning chemicals, and labor costs make them more expensive in the long run.

Example: In a wastewater treatment plant, replacing wire mesh filters every six months costs up to 30% more annually than maintaining a durable wedge wire setup.

5. Applications in Industry

• Wedge Wire Screens: Used in water treatment, chemical processing, food and beverage filtration, mining, and oil refining, where reliability and durability are essential.

• Wire Mesh Filters: Common in low-pressure or non-corrosive environments, such as air filtration and basic screening tasks.

Johnson Wedge Wire supplies precision-engineered wedge wire screens and filter elements tailored for each industrial application—ensuring optimal flow capacity, minimal clogging, and consistent performance.

6. Choosing the Right Filtration Solution

When selecting between wedge wire and wire mesh, consider the following:

Fluid type (viscosity and solids load)

Cleaning frequency and method

Expected operational lifespan

Total cost of ownership (not just initial price)

For systems requiring high efficiency, minimal downtime, and durability, wedge wire screens remain the superior choice.

FAQ: Common Questions About Wedge Wire vs. Wire Mesh

1. Why do wedge wire screens last longer than conventional wire mesh filters?

Their welded V-profile structure distributes stress evenly, preventing deformation and enhancing resistance to abrasion and corrosion.

2. Can wedge wire filters handle high-pressure industrial processes?

Yes. Their structural integrity and welded construction make them suitable for high-pressure or high-temperature environments.

3. Is stainless steel 316L the best material for wedge wire screens?

Yes. 316L offers excellent resistance to saltwater, acids, and chemicals, making it ideal for wastewater, food-grade, and petrochemical filtration.

4. How do I clean a wedge wire screen effectively?

Use high-pressure backwash or ultrasonic cleaning. The smooth surface allows particles to be flushed away without damaging the slot openings.

5. Are wedge wire screens compatible with existing filtration systems?

Yes. Johnson Wedge Wire can custom-engineer retrofit designs compatible with most industrial housings or baskets.

Wedge wire screens clearly outperform conventional wire mesh filters in cleaning efficiency, service life, and overall cost-effectiveness. For industrial sectors prioritizing uptime and precision, such as wastewater treatment, petrochemical refining, and food processing, they represent the smarter, more sustainable choice.