Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Industrial processes that handle slurries, suspended solids, or abrasive particulate loads often struggle with filtration systems that clog, wear prematurely, or fail under high pressure. These challenges are common in wastewater treatment plants, mining operations, food manufacturing facilities, pulp and paper mills, and chemical processing plants. When solids concentrations climb, traditional filter media, especially woven wire mesh and perforated plates, reach their mechanical limits.

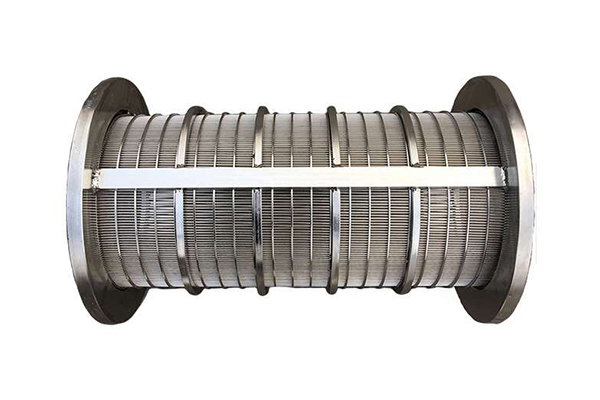

Wedge wire screens offer a practical and durable solution for these high-solids environments. Their V-shaped wire profile, continuous slot openings, and welded construction deliver consistent flow and resistance to blinding, even under extreme operating loads.

Filtration problems in high-solids applications usually follow similar patterns:

1. Rapid clogging

Woven mesh and perforated screens trap solids within the media. As solids accumulate, flow declines sharply, requiring frequent shutdowns and manual cleaning.

2. Structural deformation

Under heavy slurry load or high differential pressure, conventional screens deform. This deformation changes the opening size, making the filtration less predictable and often leading to premature failure.

3. Abrasion and corrosion

Abrasive solids, common in mining, wastewater grit, and industrial process streams, quickly wear through wire mesh. Chemical exposure accelerates corrosion, shortening the service life even further.

These recurring issues increase operational costs and create unplanned downtime, pushing operators to search for a more robust alternative.

Wedge wire screens are engineered for heavy-duty solids–liquid separation. Their unique construction offers several practical advantages:

1. Non-Clogging V-Shaped Profile

The tapered wire profile allows solids to slide over the surface instead of getting trapped. The slot opens inward, promoting free flow and significantly reducing blinding.

2. Continuous Slot Openings

Precise, continuous slots ensure consistent separation efficiency. Operators can choose slot sizes to match the exact particle retention required for wastewater, slurry, or industrial process streams.

3. High Mechanical Strength

Stainless steel 304, 316, and 316L wedge wire screens resist bending and deformation under heavy load. This makes them suitable for high-pressure filtration, thickened sludge, and abrasive applications.

4. Long Service Life

Wedge wire screens maintain predictable performance over time. Their welded structure offers exceptional resistance to wear, making them more durable than woven wire mesh in high-solids environments.

5. Easier Cleaning and Maintenance

The smooth, polished surface resists material buildup. Most systems can be cleaned using backwash cycles or simple high-pressure water jets.

These benefits make wedge wire screens ideal for applications where reliability, uptime, and filtration consistency are essential.

Click here to learn more: Wedge Wire Vs Conventional Wire Mesh

Wedge wire screens are widely used across industries where solids loading is high:

Wastewater treatment: primary screening, sludge thickening, grit removal

Mining and mineral processing: slurry classification, dewatering

Food and beverage: starch recovery, fruit pulping, grain processing

Chemical and petrochemical: catalyst recovery, solvent filtration

Pulp and paper: fiber separation, reject screening

In each of these sectors, the shift from woven wire mesh to wedge wire screens offers measurable improvements in throughput and maintenance reduction.

When choosing a wedge wire screen for demanding process conditions, the following specifications matter:

• Slot size: Determines particle retention and flow capacity

• Material grade: Stainless 304/316/316L for corrosion resistance; duplex for extreme conditions

• Wire profile: Influences open area and strength

• Support rod configuration: Affects structural rigidity

• Screen format: Panels, cylinders, baskets, lateral assemblies, drum screens

A well-matched screen design ensures stable operation and predictable performance, even under severe solids loading.

Operators who switch to wedge wire screens often report clear improvements:

Reduced maintenance interruptions

Higher filtration throughput

Longer equipment life

Lower operating costs

Better overall process stability

These outcomes help explain why wedge wire screens have become the preferred solution for demanding solids-liquid separation tasks.

Get Free Quotes for Wedge Wire Screens for High-Solids Filtration

1. What makes a screen suitable for high-solids filtration?

A screen must provide structural strength, consistent openings, and a surface geometry that prevents material packing. It must withstand abrasive contact and high differential pressure without deforming.

2. Why do woven wire mesh filters clog more easily?

Woven mesh traps particles inside the weave structure. As solids accumulate within the fabric, the effective open area decreases, resulting in a rapid decline in flow.

3. How do wedge wire slot sizes affect performance?

Smaller slots improve particle retention but reduce flow; larger slots increase capacity but capture fewer particles. Choosing the right balance depends on the process requirements.

4. Are wedge wire screens suitable for abrasive slurries?

Yes. The welded stainless steel structure offers excellent wear resistance, making these screens well-suited for mining, grit removal, and other abrasive duties.

5. Can wedge wire screens be integrated into existing filtration systems?

In most cases, wedge wire components can be customized to fit existing housings or equipment, allowing operators to upgrade performance without redesigning the entire system.