Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

When dealing with high-solids filtration, screen selection directly impacts clogging frequency, throughput stability, and maintenance cost.

Two of the most common options, wedge wire screens and perforated plates, are often considered interchangeable. In reality, their performance differs significantly under high-solids conditions.

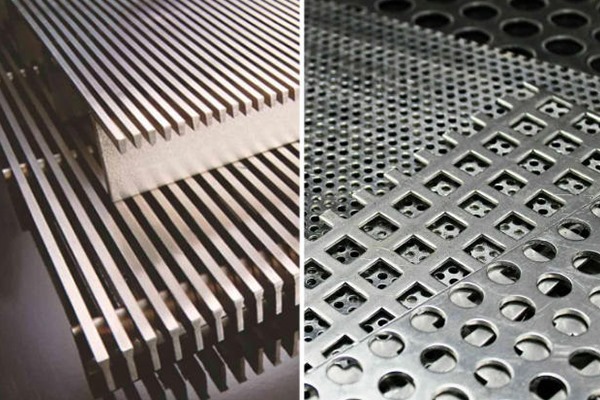

A wedge wire screen is a filtration device made from V-shaped profile wire welded to support rods, creating self-cleaning slots that resist clogging under high-solids conditions.

A perforated plate is a flat or curved metal plate with round or slotted holes created by punching or drilling.

High-solids streams, such as wastewater influent, mining slurry, pulp stock, or industrial effluent, create three major problems:

• Rapid surface blinding

• Uneven flow distribution

• Increased cleaning and downtime

Screen geometry determines how well these challenges are managed.

✔ Wedge Wire Screen Design

• V-shaped wire profile

• Slots widen in the flow direction

• Solids are retained on the surface, not inside the slot

• High open area with structural strength

✔ Perforated Plate Design

• Straight cylindrical or slotted holes

• Solids can lodge inside the holes

• Limited open area due to plate thickness

• Higher risk of irreversible clogging

| Performance Factor | Wedge Wire Screen | Perforated Plate |

|---|---|---|

| Clogging resistance | Excellent (self-cleaning slots) | Poor to moderate |

| Open area | High (up to 20–30%+) | Limited |

| Flow stability | Consistent | Drops quickly as holes blind |

| Cleaning frequency | Low | High |

| Backwash efficiency | Very high | Often ineffective |

| Service life | Long | Shorter under abrasive solids |

Perforated plates trap solids inside the hole geometry. Once lodged, particles are difficult to remove, even with backwashing.

Wedge wire screens retain solids on the surface, allowing them to slide off naturally or be removed during backwash. This design is why wedge wire performs better in streams with:

• Fibers

• Hair

• Organic solids

• Abrasive particles

In real operations, screen selection affects more than filtration quality.

✔ Perforated plates often lead to:

• Frequent shutdowns

• Manual cleaning

• Higher labor cost

• Premature replacement

✔ Wedge wire screens typically deliver:

• Longer cleaning cycles

• Reduced downtime

• Lower total cost of ownership

✔ Wedge Wire Screens Are Preferred For:

• Municipal wastewater treatment

• Mining slurry screening

• Pulp & paper processing

• Food and beverage separation

• Intake and pretreatment systems

✔ Perforated Plates Are Typically Used For:

• Low-solids applications

• Coarse screening

• Situations with minimal fouling risk

✔ Choose a wedge wire screen if:

• Solids loading is high

• Clogging has been a recurring issue

• Stable flow is critical

• Maintenance access is limited

✔ Choose a perforated plate only if:

• Solids concentration is low

• Budget constraints outweigh lifecycle cost

• Frequent cleaning is acceptable

For high-solids filtration, wedge wire screens consistently outperform perforated plates in clogging resistance, operational stability, and long-term cost efficiency.

While initial cost may be higher, wedge wire screens deliver measurable performance and maintenance advantages over time.

Yes. Wedge wire screens provide better clogging resistance and more stable flow in wastewater applications with high solids content.

Because solids lodge inside straight holes, making them difficult to remove during backwash or rinsing.

Initial cost is higher, but lifecycle cost is typically lower due to reduced maintenance and longer service life.

Yes. Slot size, wire profile, material grade, and geometry can be customized for specific process conditions.