Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Water intake systems are essential in hydropower, irrigation, municipal water supply, and industrial processes. Their role is to allow water to enter a system while preventing debris, sediment, and aquatic life from reaching downstream equipment.

Many traditional intake screens rely on mechanical systems such as drum or traveling screens. These solutions often require external power, regular maintenance, and complex cleaning systems. In remote locations or environmentally sensitive projects, these requirements can increase operating costs and reliability risks.

As a result, engineers increasingly select passive intake screening technologies that use hydraulic behavior instead of moving parts. One of the most effective and widely applied principles behind these systems is the Coandă effect.

The Coandă effect is a fluid dynamics phenomenon in which a flowing fluid naturally follows a nearby curved surface rather than separating from it. This behavior is caused by pressure differences within the fluid's boundary layer.

In intake screen applications, the Coandă effect allows water to adhere to a curved screen surface while debris and aquatic organisms remain in the surface flow. Clean water is drawn through narrow slots in the screen, while solids are carried away downstream.

This principle is well established in hydraulic engineering and provides a reliable basis for passive intake screening.

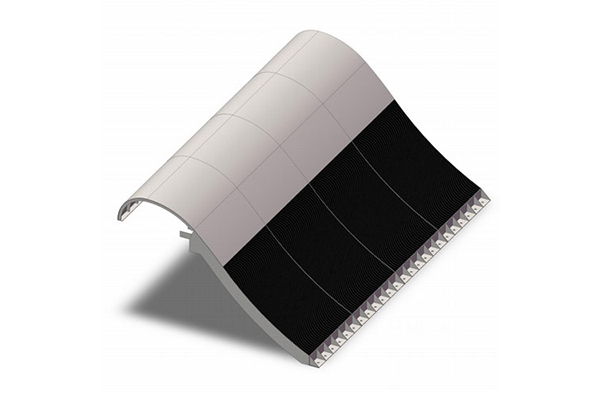

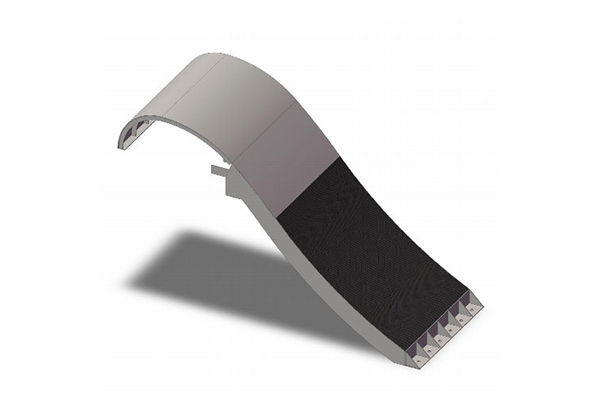

• Curved Surface and Flow Attachment

A Coandă intake screen uses a curved or inclined profile formed by wedge wire elements. As water flows over the screen, it accelerates and remains attached to the surface, creating a stable and predictable flow layer.

• Slot Openings and Velocity Control

Wedge wire screens feature continuous slot openings that are narrow at the surface and wider at the base. This geometry allows water to pass through efficiently while preventing larger particles from entering the intake.

Water velocity through the slots is lower than the surface flow velocity. This velocity difference supports debris rejection and reduces the risk of harm to aquatic life.

• Continuous Separation of Water and Solids

Clean water passes through the slots into the intake chamber. Debris, sediment, and organisms remain in the surface flow and are continuously transported away without mechanical cleaning.

✔ Wedge Wire Construction

Most Coandă intake screens are manufactured from stainless steel wedge wire (Vee wire). This profile provides precise slot openings, high structural strength, and a smooth surface that supports stable flow attachment.

Key benefits include:

• High open area

• Reduced clogging risk

• Long service life

• Consistent hydraulic performance

✔ Slot Size and Screen Geometry

Slot openings typically range from 0.25 mm to several millimeters, depending on application requirements. Screen curvature and installation angle are selected to balance flow attachment, debris transport, and hydraulic efficiency.

✔ Materials and Durability

Common materials include 304, 316, and duplex stainless steel, selected based on water chemistry and corrosion conditions. Proper material selection improves durability and reduces lifecycle cost.

✔ No Moving Parts Design

The absence of moving components simplifies operation and minimizes mechanical failure risk.

Coandă intake screens are considered self-cleaning because debris does not accumulate on the screen surface. Continuous surface flow and gravity transport solids away from the intake face.

Unlike mechanical screens, no brushes, sprays, or backwash systems are required. As long as design flow conditions are maintained, the screen operates continuously with minimal maintenance.

Key advantages include:

• Low head loss

• Continuous debris rejection

• Fish-friendly approach velocities

• No external power requirement

• Low maintenance demands

• Long operational life

These features make Coandă intake screens suitable for both remote installations and systems seeking operational simplicity.

• Hydropower

Coandă intake screens are widely used in small and medium hydropower plants, where reliable debris exclusion and fish protection are required.

• Irrigation and Agriculture

In irrigation canals and agricultural intakes, Coandă screens effectively exclude leaves, sediment, and organic debris while maintaining stable flow.

• Municipal and Industrial Water Supply

For raw water intakes, Coandă screens help protect pumps and treatment equipment by reducing solids loading.

• Cooling and Process Water

Industrial cooling and process water systems benefit from the reliability and low maintenance of passive intake screening.

| Feature | Coandă Intake Screen | Drum Screen | Traveling Screen |

|---|---|---|---|

| Moving Parts | No | Yes | Yes |

| Energy Use | None | Moderate | High |

| Maintenance | Low | Medium | High |

| Fish Protection | High | Medium | Low |

Where hydraulic conditions permit, Coandă intake screens provide a simpler and more reliable alternative to mechanical systems.

Limitations and Design Considerations

Coandă intake screens require suitable hydraulic conditions to operate effectively. Important factors include:

• Adequate available head

• Proper approach velocity

• Correct screen sizing and angle

• Site-specific debris characteristics

Engineering evaluation is essential to ensure reliable performance.

How to Specify a Coandă Intake Screen

Key specification parameters include:

• Design flow rate

• Slot opening size

• Water quality and debris load

• Installation geometry

• Structural and environmental requirements

Custom wedge wire designs are often necessary to meet site-specific conditions.

Low approach velocities and passive operation make Coandă intake screens well-suited for environmentally sensitive projects. They are frequently selected where the protection of fish and aquatic life is a priority.

The Coandă effect provides a proven hydraulic foundation for passive intake screening. When combined with precision-engineered stainless steel wedge wire construction, Coandă intake screens deliver reliable debris exclusion, low maintenance operation, and environmental protection.

For hydropower, irrigation, municipal, and industrial water intake systems with suitable hydraulic conditions, Coandă effect intake screens offer a durable and efficient solution.

Get A Free Quote for YuanLv Wedge Wire Coanda Intake Screens