Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

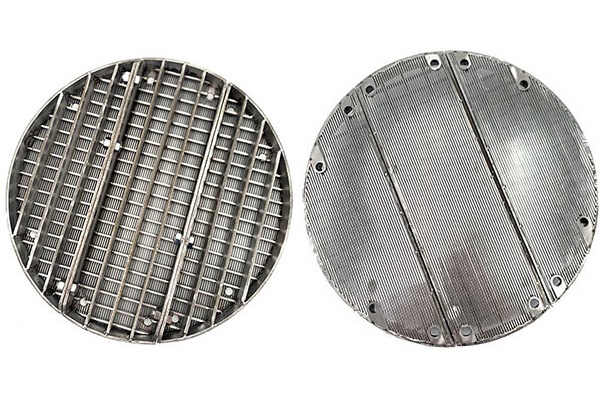

A Johnson catalyst bed support is a structural reactor internal installed at the base of a catalyst bed. Its primary function is to support the weight of the catalyst, prevent media loss, and allow process fluids to pass evenly through the reactor.

Designed for fixed-bed reactors, these reactor internals for refining are widely used in hydrotreating, hydrocracking, catalytic reforming, and other hydroprocessing units.

Unlike solid plates or perforated supports, Johnson catalyst bed supports typically use wedge wire (Vee wire) construction, which creates continuous slots for controlled flow and high mechanical strength.

Key functions include:

• Supporting heavy catalyst loads

• Retaining catalyst particles of defined sizes

• Promoting uniform flow distribution

• Minimizing pressure drop

• Withstanding high temperature and pressure conditions

Catalyst performance is directly linked to flow uniformity and mechanical stability. Poorly designed support systems can lead to:

• Channeling and maldistribution

• Catalyst crushing or attrition

• Increased pressure drop

• Premature catalyst failure

A well-engineered catalyst support grid ensures that process fluids contact the catalyst evenly, improving reaction efficiency and extending catalyst life.

Johnson catalyst bed supports use Vee-shaped wire profiles welded to support rods. This design creates a continuous slot opening that is wider on the downstream side, reducing the risk of clogging.

Technical advantages of wedge wire catalyst supports:

• High open area for efficient flow

• Self-supporting, rigid structure

• Excellent resistance to plugging

• Precise slot control for catalyst retention

• Long service life in harsh refining conditions

These features make Johnson wedge wire catalyst bed supports suitable for fixed bed reactors operating under high temperature, high pressure, and corrosive environments.

In refining reactors, catalyst bed supports often work as part of a complete reactor internals assembly, which may include:

• Catalyst support grids

• Catalyst retention grids

• Hold-down grids

• Flow distribution grids

• Collection grids

Together, these internals form a fixed-bed reactor support system that ensures mechanical stability and process efficiency throughout the catalyst cycle.

Material selection is critical for durability and safety in refining applications. Common materials include:

• Stainless steel 304 for general refining services

• Stainless steel 316 and 316L for improved corrosion resistance

• Duplex stainless steel for high-strength and aggressive environments

• Heat-resistant alloys for elevated operating temperatures

These materials provide excellent resistance to corrosion, erosion, and thermal stress, supporting long-term reactor operation.

Johnson catalyst bed supports are widely used across refining and petrochemical processes, including:

• Hydrotreating reactors

• Hydrocracking units

• Catalytic reforming reactors

• Desulfurization reactors

• Hydrogenation reactors

• Fixed-bed petrochemical reactors

Their low pressure drop and high load-bearing capacity make them suitable for both small and large-diameter reactors.

Yes. Custom-fabricated catalyst bed support grids are often required to match reactor dimensions, catalyst size, and process conditions. Engineering considerations typically include:

• Reactor diameter and height

• Catalyst particle size distribution

• Operating pressure and temperature

• Load requirements

Installation and maintenance constraints

Custom Johnson catalyst bed supports ensure optimal fit and reliable performance throughout the reactor’s operating life.

From an operational perspective, a well-designed catalyst bed support system delivers measurable benefits:

• Improved flow distribution

• Reduced pressure drop

• Enhanced catalyst utilization

• Lower risk of unplanned shutdowns

• Extended maintenance intervals

These advantages directly support refinery goals of higher throughput, improved efficiency, and long-term operational stability.

Frequently Asked Questions

1. What is the main purpose of a catalyst bed support grid?

Its primary purpose is to support catalyst weight while allowing uniform fluid flow through the reactor.

2. Why are wedge wire supports preferred over perforated plates?

Wedge wire designs offer higher open area, lower pressure drop, and better resistance to clogging.

3. Are Johnson catalyst bed supports suitable for high-temperature refining units?

Yes. When manufactured from appropriate stainless or alloy materials, they are designed for high-temperature and high-pressure operation.

4. Can catalyst bed supports be used in large-diameter reactors?

Yes. Johnson support grids are commonly engineered for large-diameter and heavy-load refining reactors.

Johnson catalyst bed support systems are a fundamental component of modern reactor internals used in refining. By combining robust mechanical strength with precise flow control, wedge wire catalyst supports enable refiners to achieve stable operation, efficient catalyst utilization, and extended equipment life.

For fixed bed reactors in oil refining and petrochemical plants, selecting a properly engineered Johnson catalyst bed support is not just a design choice; it is a critical factor in long-term reactor performance and process reliability.