Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

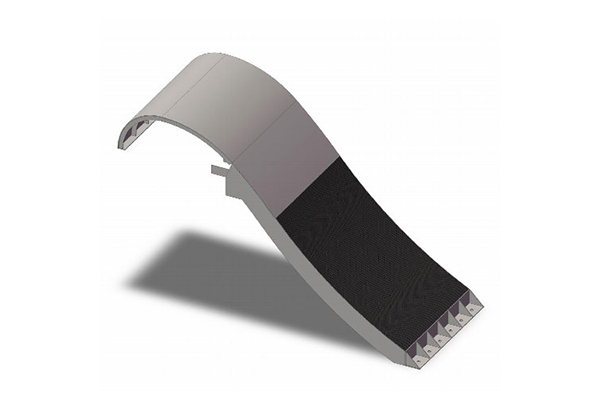

A Coanda screen is a specialized wedge wire intake screen designed to separate water from debris such as leaves, sediment, and aquatic life. It is installed at water intakes—such as rivers, streams, or dam outlets—to provide clean, filtered water for downstream applications.

Coanda screens are an innovative solution widely used in hydropower plants, irrigation systems, water intake structures, and wastewater treatment facilities. Known for their self-cleaning ability and efficiency in filtering debris, they rely on the Coanda effect—a natural hydraulic principle that allows water to adhere to a curved surface.

So, how does a Coanda screen work?

▪ Water Flow Over the Weir

Water is directed over a sharp crest or weir and flows onto the screen surface.

▪ The Coanda Effect in Action

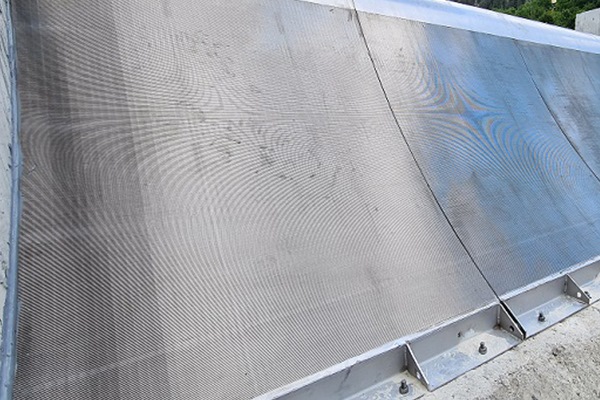

Due to the Coanda effect, the water clings to the curved screen surface, following its slope rather than separating immediately.

▪ Separation of Water and Debris

Water passes through the wedge wire screen slots, which are precisely engineered (often 0.25 -1.0mm wide).

Debris, sediment, and fish slide over the surface and are carried downstream, reducing clogging.

▪ Self-Cleaning Mechanism

Because debris continues along the screen surface without accumulating, the system operates with minimal manual cleaning.

This unique process enables a high flow rate, low head loss, and effective filtration with very little maintenance.

▪ Wedge Wire Construction: Strong stainless steel structure with precise slot openings.

▪ Inclined Orientation: Typically installed at a steep angle (30–45°) to maximize flow efficiency.

▪ Self-Cleaning Surface: Uses hydraulic forces, not brushes or moving parts, to stay clean.

▪ Low Head Loss: Maintains efficiency even with continuous debris loads.

▪ Scalable Design: Suitable for small irrigation projects as well as large hydropower intakes.

Coanda screens are used across multiple industries:

▪ Hydropower Plants - To filter intake water while protecting turbines.

▪ Irrigation Systems - To provide clean water for agricultural use.

▪ Water Treatment Plants - For pre-filtration before further processing.

▪ Fish Protection Systems - Preventing aquatic life from entering intakes.

▪ Wastewater Treatment - To separate solids and debris before secondary treatment.

▪ Small Hydro Projects - Where efficiency and low maintenance are critical.

Our Coanda screens are a proven, efficient, and sustainable solution for water intake and filtration systems. By harnessing the Coanda effect, they achieve self-cleaning operation, high efficiency, and environmental protection with minimal maintenance.

Whether used in hydropower, irrigation, or wastewater treatment, Coanda screens deliver long-term reliability and performance, making them a smart investment for modern water management projects.

Frequently Asked Questions (FAQs)

1. How do Coanda screens prevent clogging?

By using the Coanda effect, water adheres to the screen while debris flows over, keeping the surface clear.

2. What is the slot size of a Coanda screen?

Typical openings range from 0.25mm to 1.0mm, depending on the application.

3. Can Coanda screens handle fish passage?

Yes, they are widely used for fish protection in rivers and hydropower intakes.

4. Are Coanda screens expensive?

The initial cost is higher than conventional screens, but reduced maintenance and long service life make them cost-effective.

5. Where are Coanda screens most commonly used?

They are primarily installed in hydropower plants, irrigation systems, and water treatment facilities.