Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Coal screening plants operate under demanding conditions, where performance, durability, and efficiency are key factors in determining profitability. In recent years, wedge wire screens have become a preferred choice for coal screening applications, replacing traditional woven wire or perforated plates.

This case study examines the real-world performance of stainless steel wedge wire screen panels in a coal processing facility, detailing the improvements in throughput, wear resistance, and return on investment (ROI).

A major coal preparation plant in Australia faced recurring issues with its vibrating screen panels and dewatering screens. Traditional woven wire mesh panels suffered from rapid wear, blinding, and inconsistent particle separation. As a result, plant efficiency dropped, maintenance costs increased, and production downtime became a significant burden.

The plant operators sought a cost-effective screening solution capable of handling fine coal particles, high moisture content, and abrasive materials - without compromising screening efficiency or maintenance intervals.

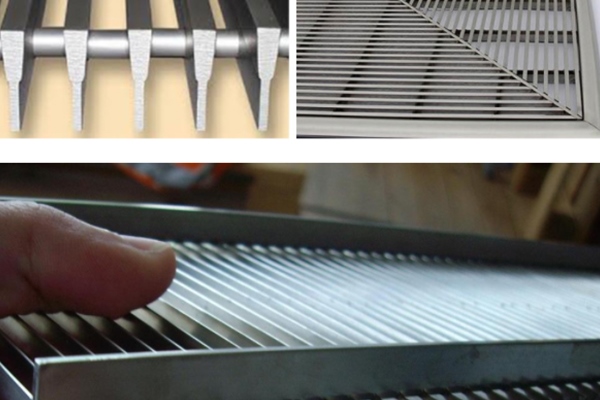

After evaluating several alternatives, the plant management selected custom wedge wire screen panels designed with precise slot openings and V-shaped profiles. Manufactured from stainless steel 304 and 316L, these panels offered excellent corrosion resistance and high mechanical strength.

Key technical features included:

• Slot size: 0.3–2.0 mm (optimized for fine coal separation)

• Profile wire shape: Trapezoidal V-wire to prevent clogging

• Support rod spacing: Engineered for optimal load distribution

• Surface finish: Self-cleaning design for continuous operation

The screens were installed on the primary and secondary coal dewatering units, as well as the sieve bend screens, within the plant.

✔ Performance Results

Within six months of operation, the plant recorded a marked improvement in screening performance and process stability.

1. Screening Efficiency

The wedge wire screens increased particle separation accuracy by more than 20% compared to woven wire mesh. The self-cleaning surface reduced blinding and allowed for consistent flow rates even under heavy slurry conditions.

2. Reduced Downtime

The average screen replacement cycle extended from 4 weeks to over 12 weeks. Maintenance teams reported faster changeouts due to the modular panel design, lowering maintenance labor by 35%.

3. Dewatering Improvement

Water recovery improved by approximately 18%, resulting in drier coal output and reduced moisture transport costs. The precise aperture size and V-wire configuration enhanced liquid-solid separation efficiency.

4. Cost and ROI

Although the initial investment in wedge wire screens was higher, the long-term ROI was significant. Reduced maintenance, improved yield, and consistent production led to a return on investment within 9 months.

✔ Economic Analysis

| Parameter | Before (Woven Mesh) | After (Wedge Wire Screen) | Improvement |

| Screening efficiency | 75% | 90% | +20% |

| Screen life | 1 month | 3 months | +200% |

| Maintenance cost | 100% | 65% | -35% |

| Plant uptime | 88% | 97% | +9% |

| ROI period | – | 9 months | – |

This performance data confirmed that wedge wire screen panels deliver superior long-term value through durability and process optimization.

• High strength and rigidity: Ideal for heavy-duty coal processing environments.

• Anti-clogging surface: V-shaped profile wires prevent particle lodging.

• Customizable slot openings: Adaptable to various coal particle sizes.

• Corrosion and abrasion resistance: Suitable for wet screening and slurry applications.

• Long service life: Reduced need for frequent replacement lowers operating costs.

From this case, several key lessons emerged for coal screening plant operators:

• Match slot size to particle size: Optimal separation depends on correct slot configuration.

• Use stainless steel wedge wire panels in high-moisture or corrosive environments for extended life.

• Regular performance monitoring ensures early detection of wear and maintains screening efficiency.

• Evaluate ROI holistically: Consider reduced downtime and improved recovery rates, not just initial cost.

This case study demonstrates that wedge wire screens are a reliable, high-performance solution for coal screening plants seeking to enhance productivity and profitability. The transition from woven mesh to stainless steel wedge wire screen panels resulted in measurable gains in screening efficiency, plant uptime, and return on investment.

For coal processing facilities aiming to improve operational performance and reduce maintenance costs, wedge wire screen technology represents a proven and sustainable upgrade path.

Contact Information

E-mail: admin@yuanlvfilter.com

WhatsApp: 8613653285589

1. What is a wedge wire screen used for in coal screening plants?

Wedge wire screens are used to separate coal particles by size, remove water, and prevent oversize materials from entering downstream processes. Their high strength and anti-clogging design make them ideal for dewatering and fine coal recovery.

2. Why are wedge wire screens better than woven mesh?

Unlike woven mesh, wedge wire screens have a continuous V-shaped profile that resists clogging and provides a smooth screening surface. This design improves throughput, reduces maintenance, and extends lifespan significantly.

3. How long do wedge wire screens last in coal screening applications?

Depending on the coal type and operation intensity, stainless steel wedge wire panels typically last three to five times longer than conventional woven mesh panels.

4. What slot size is best for coal screening?

Slot openings between 0.3 mm and 2.0 mm are commonly used. The exact size depends on the particle size distribution and the desired separation efficiency.

5. Are wedge wire screens cost-effective for coal plants?

Yes. While the initial cost is higher, the total ROI is achieved within 6–12 months due to longer service life, improved throughput, and reduced downtime.

6. Can wedge wire screens be customized?

Absolutely. Manufacturers can customize slot openings, dimensions, materials, and frame types to match specific process requirements for coal processing, dewatering, or classification.