Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

With excellent high-pressure resistance and stable filtration effect, YUANLV sintered metal wire mesh filters can be applied for diffuser screens, centrifuges, breather vents, fluidized beds, chromatography, polymer, petrochemical, hydraulic filters, and more.

Our main sintered filter products include: Five-layer sintered mesh, Sintered mesh filter plate, Sintered mesh with perforated metal, Sintered metal filter cartridge, Sintered metal filter disc, Pleated sintered mesh filter, Sintered cone filter,etc.

The multi-layer sintered mesh is superior to common metal mesh for offering higher durability, strength, hardness and good position of pores. Sintered mesh offers high flow rates with average loadings and features adequate cleaning and backwash properties.

With virtually constant and adequate flow resistance and excellent backwash characteristics, the higher pressure loadings can be handled.

The sintered wire mesh is fit for stable deaeration filters, nutsche filters, dryers, cleaning baskets, filter drums for quenching systems, aeration parts, pneumatic conveyors and more.

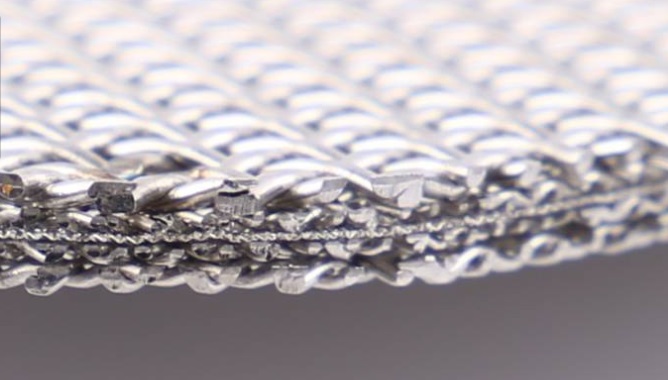

Five-layer sintered mesh is a standard combination of five layers of wire meshes with different openings and diameters through sintering (diffusion-bonding) in vacuum, which improves the characteristics of stainless steel woven wire mesh.

By bonding the contact points of different wire meshes together, five-layer sintered mesh has become an integrated porous material with enhanced mechanical strength, high permeability, and better structural integrity, because the sintering process remains the good filtration rating of the finest mesh layer, also the mechanical strength of the coarser support layers.

Besides all of that, heat and pressure are combined to create molecular diffusion welds at every intersection of the wire mesh where the wires cross over and under one another, which in turn enhances the temperature and pressure resistance of the sintered mesh.

For its distinct features, five-layer sintered mesh is widely used for diffusing, breather vents, filters in many areas such as gas distribution, polyester filtration, water treatment, etc.

Typical applications of five-layer sintered mesh include filtration of polymer, food, water, cosmetic, pharmacy, chemicals and hydraulic fuels. It is also used for fluidization of bulk materials in wagons, conveyors, driers, coolers and storage silos.

1. Which industries can use five-layer sintered mesh for filtration?

Polymer filtration, petrochemical and refining, pharmaceutical production, natural gas, new energy and other industries, or the treatment of dust particles such as metal powders/vapors, gelled particles, carbon powder, talcum powder, plant spores, bacteria, and other dust particles.

2. What information needs to be provided for customized five-layer sintered mesh?

We can design and customize five-layer sintered mesh products according to your specific needs. Just provide us with the following basic information: shape, application, mounting structure, flow rate, pressure drop, working pressure, working temperature, and material, and then our experienced engineers will provide you with suitable solutions for your reference and choice.

If you need to consult the price, please contact the business department by E-mail:

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

Previous: Wire Mesh Filter Disc