Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

The wedge wire screens are the primary filtration barrier against sediment, debris, and biological contaminants in riverbank filtration systems.

Riverbank filtration relies on the natural filtration capacity of riverbanks and subsoil as river water infiltrates and percolates through sediment layers. To harness this process effectively, intake screens are installed at strategic locations, typically near infiltration wells or galleries. Wedge wire screens, particularly those manufactured from stainless steel 304 or 316L, are ideal for such applications due to their:

✔ Corrosion resistance in natural water environments

✔ Precise slot openings (commonly 0.2 mm to 1.0 mm) for controlled filtration

✔ High open area, maximizing water throughput while minimizing clogging

✔ Non-clogging V-wire design, which ensures continuous and uninterrupted flow

These characteristics make wedge wire screens highly durable and low-maintenance, even under challenging riverbank and groundwater conditions.

To meet the diverse needs of municipal, industrial, and environmental water management applications, various wedge wire screen products are utilized within riverbank filtration setups. Below are the most commonly used solutions:

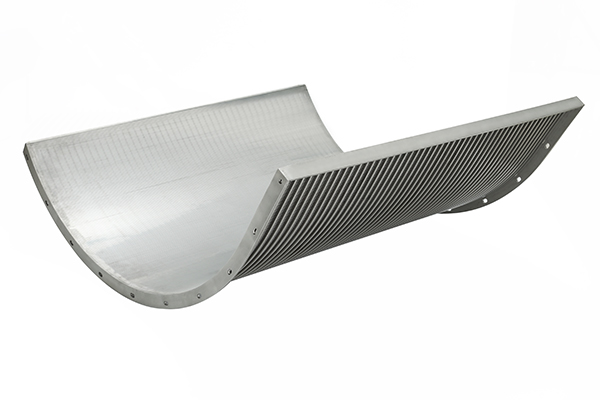

1. Sieve Bend Screens (Parabolic Screens)

Sieve bend screens, also known as parabolic screens, are static screens featuring a curved surface that separates solids from water as it flows by gravity. Ideal for pre-filtration at riverbank intake points, these screens offer:

• Excellent solids separation without power consumption

• Easy installation in gravity-fed channels

• Low operating and maintenance costs

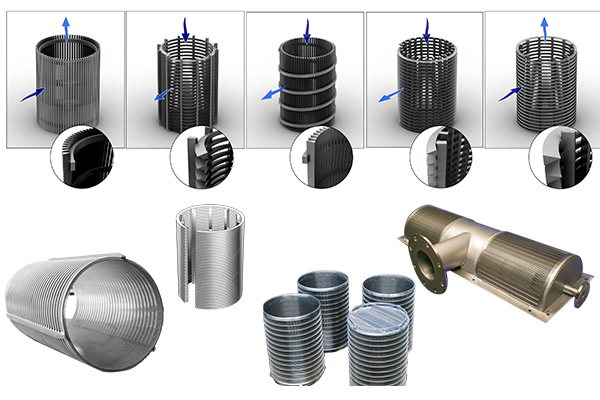

For applications where flow rates are higher and automation is essential, rotary wedge wire screens are the preferred choice. These screens rotate continuously, capturing debris while allowing filtered water to pass through.

• Ideal for larger intake systems

• Reduces the risk of biofouling and sediment build-up

• Available with customizable drum diameters and slot sizes

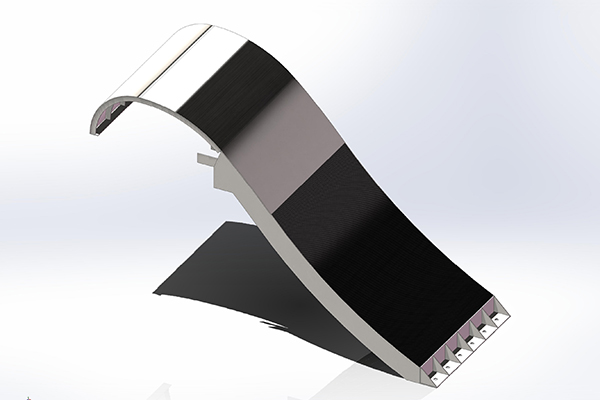

Coanda intake screens are engineered to use the Coanda effect, which enhances the separation of solids from water using a precise curvature and tilted V-wire design.

• Self-cleaning and energy-free operation

• Perfect for surface water intakes in riverbank systems

• Requires minimal maintenance, ideal for remote installations

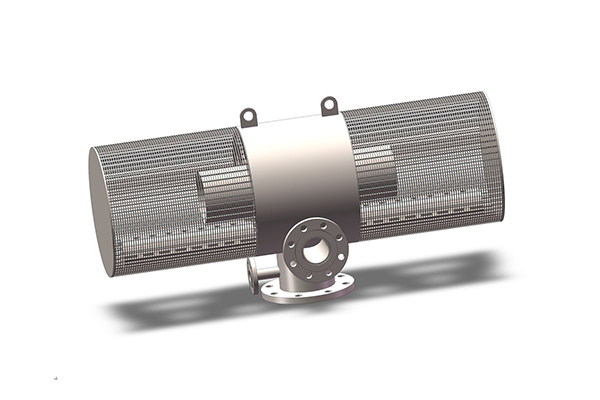

Passive wedge wire intake screens are installed directly at riverbanks or near infiltration galleries. Designed to be fish-friendly and compliant with environmental regulations, they offer:

• Protection of aquatic life

• Uniform flow to prevent hydraulic head loss

• Long service life due to marine-grade stainless steel construction

| Feature | Benefit |

| Continuous Slot Design | Prevents clogging and ensures uninterrupted flow |

| High Mechanical Strength | Withstands subsurface pressure and sediment load |

| Custom Configurations | Tailored to specific river conditions and flow rates |

| Minimal Maintenance | Reduced downtime and operational costs |

| Eco-friendly | Supports sustainable water extraction practices |

Wedge wire screens are widely deployed in municipal water treatment plants, groundwater recharge programs, and environmental restoration projects. Their versatility makes them suitable for:

✔ Drinking water supply

✔ Industrial process water intake

✔ Aquifer recharge systems

✔ Surface water abstraction

When selecting a screen for riverbank filtration, consider:

• Water flow rate and sediment load

• Slot opening size based on local water quality

• Screen configuration (flat, cylindrical, curved)

• Material grade (SS304 vs. SS316L for corrosion resistance)

• Ease of installation and maintenance

At YuanLv, we offer fully customizable wedge wire solutions, including sieve bend screens, rotary drum screens, coanda intake screens, and passive wedge wire intake filters. All products are fabricated to the highest standards, ensuring performance, durability, and compliance with local environmental regulations.

Interested in optimizing your riverbank filtration system?

Contact our engineering team today for a custom solution tailored to your site's unique water intake needs.

E-mail: admin@yuanlvfilter.com

WhatsApp: 86 13653285589