Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Catalyst recovery plays a pivotal role in sustainable and cost-effective chemical processes, aiming to recycle catalysts susceptible to deactivation factors. This process is crucial for environmental and commercial reasons, ensuring the reusability of critical catalysts over multiple cycles. One highly effective method for catalyst recovery is filtration, leveraging the chemical or physical differences between reaction mixture components.

Traditional catalyst recovery method in process filtration systems.

Provides a simple and efficient means of separating catalysts.

Modern filtering technology offering superior filtration in catalyst recovery applications.

Ensures effective separation of catalysts from reaction mixtures.

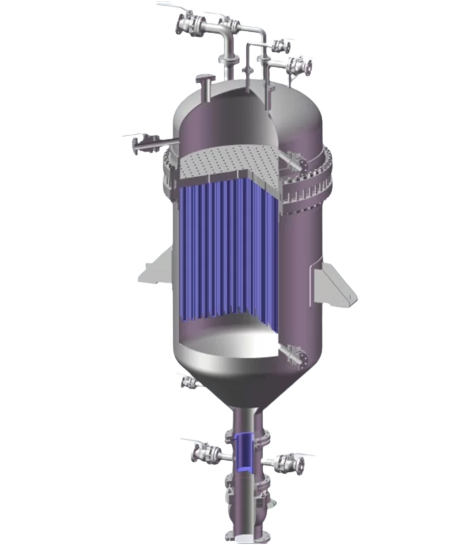

Includes candle filter housings, filter elements, back purging mechanisms, control panels, etc.

Available in materials like SS-304, SS-316, SS-316L, Duplex steels, carbon steel, and alloy metal.

Offers a comprehensive solution for efficient and controlled catalyst recovery.

To address catalyst leakage in the chemical industry, YUANLV has designed a catalyst filtration system using sintered porous metal filters. This system excels in extreme environments and intermittent production, effectively solving liquid-solid separation challenges and creating significant value for customers.

Shape Stability: Maintains structural integrity even under high pressure.

Good Mechanical Properties: Ensures durability and longevity.

Corrosion Resistance: Protects against chemical deterioration.

Good Back Flushing Performance: Enhances filter lifespan and efficiency.

Environment Protection: Customizable design contributing to environmental sustainability.

Automatic Control: Reduces worker exposure to harsh chemicals.

Filter Cake Elimination: Solves the problem of filter cake accumulation.

Oil Refining Industry (FCC, CCR): Optimizes catalyst recovery in crucial refining processes.

Polysilicon Industry: Addresses catalyst separation needs in polysilicon production.

High-Temperature Fischer-Tropsch Synthesis: Facilitates efficient recovery in high-temperature synthesis.

Fluidized Bed Reactor: Ensures catalyst recovery in fluidized bed reactor applications.

Organosilicone Production: Meets catalyst separation requirements in fine chemical production.

For detailed product information or customized solutions, please reach out to our Sales Engineers. We are committed to providing cutting-edge catalyst recovery solutions tailored to your specific needs.

E-mail:admin@yuanlvfilter.com