Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

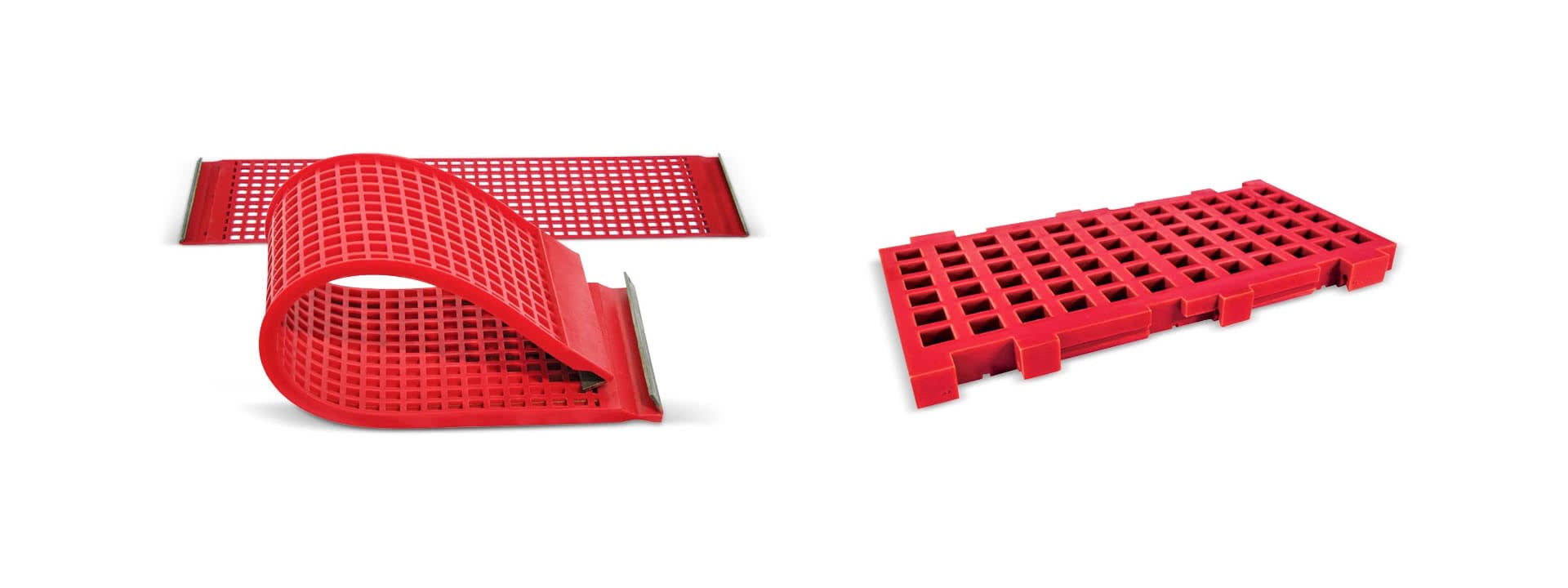

The polyurethane screen panel, crafted from polyurethane materials, serves as a versatile mesh screen suitable for screening diverse materials. Its applications extend to various substances, including coal, gangue, coke, slaked lime, and other moisture-prone materials. This screen effectively tackles the issue of clogging and stickiness encountered during the screening of wet materials in different vibrating screens. Its implementation significantly enhances the output and reliability of the screening system.

Polyurethane screen panels, crafted from premium polyurethane materials, stand out as a versatile solution catering to various industries. These panels boast exceptional durability, resistance to abrasion, and elevated screening efficiency. Their flexibility and extended lifespan make them resilient against heavy loads and screen plugging, offering a reliable screening system.

High Screening Efficiency: Outperforms regular screens by 2 to 5 times.

Enhanced Bearing Capacity: Approximately 2.5 times more than rubber sieves.

Extended Service Life: Lasts from six months to over a year.

Superb Abrasion and Corrosion Resistance: Suitable for water or oil mediums.

Low Maintenance and Replacement: Prevents hole plugging and requires no washing.

Reduced Noise Levels: Features vibration-absorbing capabilities.

Optimized Screen Hole Design: Prevents particle blockages, ensuring seamless mesh operation.

Extensive Applications: Widely used across mining, metallurgy, coal, chemicals, and more.

Excellent Wet-Resistance: Functions efficiently even in water-based conditions.

These polyurethane screen panels find extensive application in mining, mineral processing, grading, and dehydration processes. They effectively replace metal sieves in coal, iron ore, copper, gold, and various other ore grading and screening applications. From coarse stones to fine materials, they excel in both wet and dry material separation.

Aggregate Processing

Washing Applications

Cement Manufacturing

Mining Operations

Within these industries, these screens effectively segregate materials based on size, shape, or other defining characteristics, providing a tailored screening solution for diverse process requirements.

Easily replace woven wire screens without modifications, boasting high abrasion resistance and minimal noise levels.

Modular Polyurethane Screens: Designed for easy installation, repairable and changeable individually without impacting other panels, saving time and effort during replacement.

Ideal for fine screening and dewatering applications, offering a rigid yet modular panel design.

Specialized for specific applications, delivering excellent separation efficiency。

Purchasing from reputable manufacturers ensures panels made with top-grade raw materials and manufactured in advanced facilities, promising reliability and superior performance. For any further queries, our experts are available to provide tailored solutions.

Feel free to contact us or emails: admin@yuanlvfilter.com for the best-suited polyurethane screen panels, engineered by professionals to optimize your screening operations for enhanced productivity and sustainability.