Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

Filter nozzles, or distributors, are crucial elements within filtration systems, tasked with retaining granular filter media or purifying agents inside a container.

This article delves into the workings of filter nozzles, their advantages, selection criteria, and application areas.

We highly recommend the wedge wire screen filter nozzle.

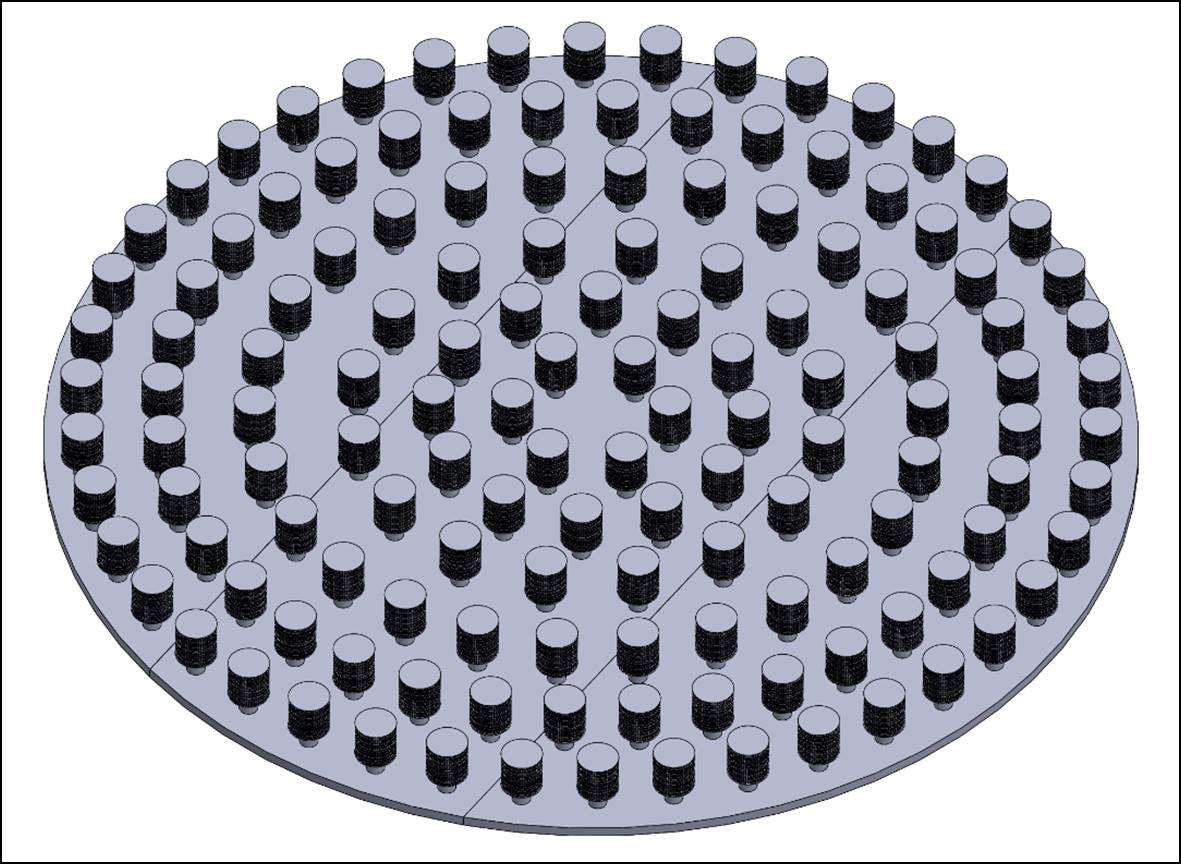

A wedge wire filter nozzle comprises a mesh or slotted element, typically made of materials such as stainless steel, PVC plastic, or ABS. The structure allows for the retention of filter media while facilitating fluid flow. The design, often featuring V-shaped wires, prevents clogging by enabling easy dislodging of trapped particles. Precise control over slot spacing ensures efficient filtration without blockages.

Non-clogging design ensures peak flow and minimizes downtime for cleaning.

Additional wire facilitates backwashing for easy maintenance.

Cylindrical shape enhances resistance to high pressures.

High-precision slot spacing accommodates various particle sizes.

Even distribution of liquid within the filter ensures optimal filtration.

Design flexibility offers multiple shapes for diverse applications.

Surface profile: Choose from flat, triangular, round, or trapezoidal wires based on filtration requirements.

Material: Consider stainless steel for stability, resistance to rust, and compatibility with diverse fluids.

Service Flow: Select nozzle size based on the desired flow rate during filtration and backwashing.

Operating Pressure: Ensure the chosen nozzle can withstand the maximum and minimum operating pressures.

Operating Cost: Opt for quality nozzles to minimize maintenance and replacement expenses.

Environmental Exposure: Select materials compatible with the operating environment, considering factors like temperature, chemicals, and corrosion resistance.

Filter nozzles find applications across various industries, including food and beverage, fertilizer production, and seawater treatment plants. Their versatility makes them indispensable for achieving efficient filtration in diverse settings.

If you want the best for your filtration, you need to select the best water filter nozzle in your projects and paying attention to specific details.

1. Particle characteristics

Understand the nature and size of the particles in a granular media bed to select a nozzle. The particle size of the media should be twice the size of the nozzle slot. To make sure that the filter media will not leak out of the nozzle slots.

2. Maximum operating flow rate

The flow rate will determine the size of the filter to be used. In other words, the number of nozzles must be adjusted to the flow rate of the fluid. Check the corresponding flow indication to select the correct nozzle.

3. Maximum and minimum operating pressure

Each filter has a maximum operating pressure it can withstand. Therefore, it is necessary to select a nozzle that matches the operating pressure of your application. The greatest care is taken with plastic nozzles or manifolds, as these can collapse at lower pressures than stainless steel ones.

4. Operating cost

One way to keep operating costs low is to make sure that you select a quality nozzle, as you can’t be opening filters for media or nozzle changes frequently.

5. Risk of environmental exposure

Finally, it would be best if you considered the environment in which a nozzle will operate, in terms of temperature, chemicals and physical environment.

ABS or Kynar nozzles and hydrospheres are the most likely to withstand chemicals or high corrosion. But not very high pressures.

Stainless steel nozzles are more durable and can be exposed to higher pressures, but are not a viable option for high salinity or acids.

Filter nozzles are indispensable components of filtration systems, offering numerous advantages such as non-clogging design, high-pressure resistance, and precise filtration. Selecting the right nozzle based on criteria like surface profile, material, and operating conditions is crucial for optimal performance and cost-effectiveness. With their wide-ranging applications and benefits, filter nozzles play a vital role in ensuring effective filtration processes across industries.