Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

The dairy industry stands as the primary producer of wastewater within the food sector, generating up to double the amount of wastewater compared to the processing of 1 m3 of milk. A substantial portion of this wastewater originates from the cleaning processes, with additional contributions from spills and tank unloading operations.

Dairy processing involves the conversion of raw milk into various products such as pasteurized milk, yogurt, cheese, butter, and ice cream. The global consumption of these products is significant and continually on the rise, paralleled by a proportional increase in wastewater production.

--Variability

--High levels of BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand)

--Fats, Oils, and Grease (FOG)

--Toxicity

--Hampering

The dairy industry's wastewater comprises water, solids, fats, and cleaning agents, and its volume and characteristics depend on factors like the type of dairy product, processing methods, and farm size. Due to high levels of organic matter, nitrogen, and phosphorus, proper treatment is essential to prevent water pollution before discharge.

The reason that the wastewater that is produced in dairies is highly variable is due to the many different sources of dairy wastewater and process water.

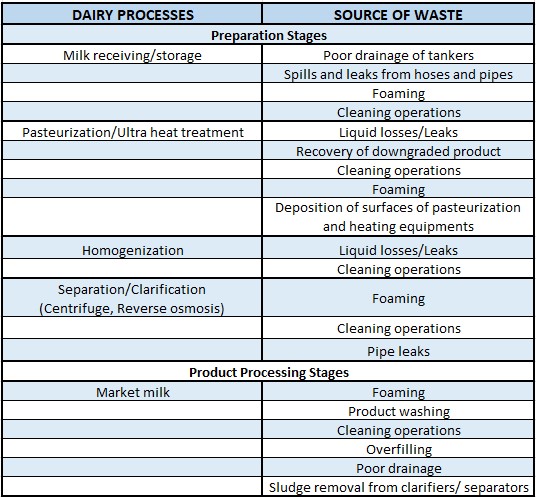

This table gives a list of some wastewater sources from the milk processing industry. As you can see, there are wastewater streams from each step in the process.

The composition of dairy wastewater varies across different product categories, necessitating a thorough understanding of the correct design of wastewater treatment plants. YUANLV employs a step-by-step process with each client to ensure accurate designs, providing effluent quality guarantees with their equipment and solutions.

The variability in dairy wastewater composition arises from diverse sources and process water. The wastewater originates from various steps in the milk processing industry, requiring a careful selection of wastewater treatment processes to avoid system failure and compliance issues.

Bag Filters: Suitable for pipeline milking, made with a bag filter fabric.

Filter Disks: Used for hand or bucket milking, available in round or rectangular shapes.

Wedge Wire Screen Filter Strainers: Designed for pipeline systems, require regular cleaning for optimal performance.

Proper filtration is crucial to ensuring the highest quality milk reaches consumers. It not only guarantees a superior product but also aids in identifying health concerns in cattle, enabling prompt action for the benefit of both animals and the bottom line of dairy farms. Effective filtration protects milking equipment from harmful particulates, leading to cost savings.

Contact Us if you can't find what you need as we have just about every type of liquid filter. If we don't, we'll find it for you at competitive prices!