Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

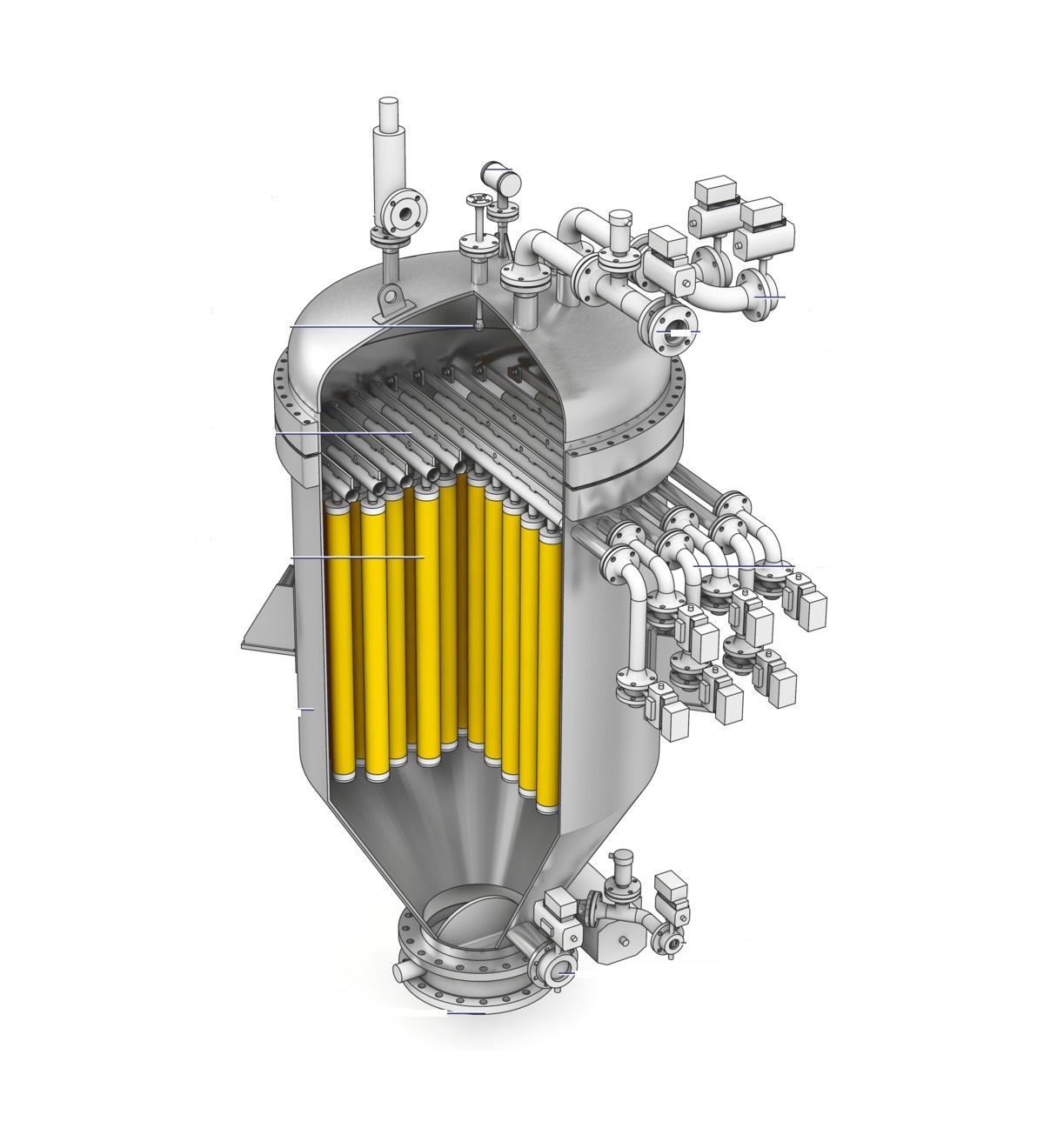

The Candle Filter stands as a specialized, self-cleaning filtration system meticulously crafted for solid-liquid separation tasks, excelling in the clarification and recovery of liquids containing minimal solids, ranging from 5% to less than 1%, and even trace amounts.

Product Details

This candle filter presents an alternative methodology for eliminating fine particles. Similar to bag filter housings, gases pass through the Candle Filter, forming a surface cake. Periodic back-flushing efficiently dislodges and removes the accumulated material. Constructed from robust metals, these filters operate at lower temperatures and boast enhanced durability. To bolster safety measures, employing a guard system is recommended, preventing uncontrolled material ingress if the filter malfunctions, thereby safeguarding downstream equipment.

Effortless Cake Discharge: Ensures excellent discharge of filtered material.

Versatile Adaptability: Easily accommodates slurry thickening needs.

Space-Efficient Design: Occupies minimal floor space.

Mechanical Simplicity: No complex sealing glands or bearings, ensuring straightforward operation.

Durable Construction: Stainless steel housing with options for special materials upon request.

Environmentally Safe: Fully enclosed operation handles corrosive and volatile liquids without environmental or health risks.

Filter Aid Flexibility: Allows addition of filter aids as required.

Minimal Liquid Loss: Employs a design that permits the drying of filter cakes, ideal for processing and recycling with minimal liquid loss.

Diverse Filtration Capability: Offers various filter aid materials catering to diversified filtration demands across industries.

Candle Filter housings find applications in Simplex and Duplex filters, proving invaluable due to their extensive filter area and high resistance to differential pressure. They excel in filtering liquids with low solid content, notably in water treatment scenarios and industries requiring exceptionally clean liquids.

Diverse Industry UtilizationThese filters play a pivotal role in handling diverse substances such as titanium dioxide, flue gas, brine clarification, red mud, china clay, fine chemicals, and more, where efficient low moisture cake filtration or high-quality polishing is imperative. | Thickening CapabilityCandle Filters also serve in thickening processes, producing concentrated, flowable slurries by extracting the liquid phase as filtrate. Their rapid cycle times and high filtration rates make them suitable for this purpose, yielding clear filtrate unlike gravity thickeners which often contain fine suspended solids in their overflows. |

Unique Design FeaturesThe cylindrical shape of Candle Filter elements aids in retaining formed cakes, maximizing filtration area as cakes thicken. This design compensates to some extent for decreased filtration rates, setting it apart from Plate, Leaf, or Filter presses. | MaintenanceRoutine maintenance is essential for Candle Filters. Regular cleaning, using a soft brush and clean water every two weeks, is necessary to counter particle buildup and maintain optimal flow rates. As continuous use leads to a reduction in wall thickness, impacting its effectiveness in removing microbes, it's recommended to replace the filters every 6-12 months for sustained efficiency. |

Candle Filters stand as versatile solutions offering thin-cake pressure filtration, encompassing cake washing, drying, reslurrying, automatic discharge, and heel filtration, all within a sealed pressure vessel.

Filter candles are composed of three integral components: a single-piece dip pipe for filtrates and gas, a perforated core supported by outer tie rods, and a filter sock. These candles can be crafted from synthetic materials, stainless steel, or higher-grade alloys. The outer tie rods ingeniously create an annular space between the core and the media, ensuring low-pressure drop operations. This setup optimizes gas expansion within the filter media sock, facilitating efficient cake discharge.

The Candle Filter's vessel or housing is meticulously constructed from stainless steel or high-grade alloys, guaranteeing durability and resilience. Within this vessel, horizontal manifolds, referred to as candle registers, are embedded. Each candle connects to a register with a secure seal to prevent any bypass. Depending on the filter size, a register can accommodate one or multiple candles. Automated valves regulate each register, ensuring optimal flow in both directions – conveying liquid filtrate forward and pressure gas in reverse to expand the filter media sock.

During the drying of the filter cake, back flushing with injected gas from the register initiates the expansion of the filter bag. As the dried filter cake expands and dislodges, it gracefully falls off, discharged through the cake drainage nozzle. Post-cake discharge, the nozzle on the register sprays liquid, cleansing the filter elements in preparation for the subsequent filtration cycle.

This intricate process ensures a seamless transition into the next filtration cycle, maintaining a high level of operational efficiency throughout.