Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

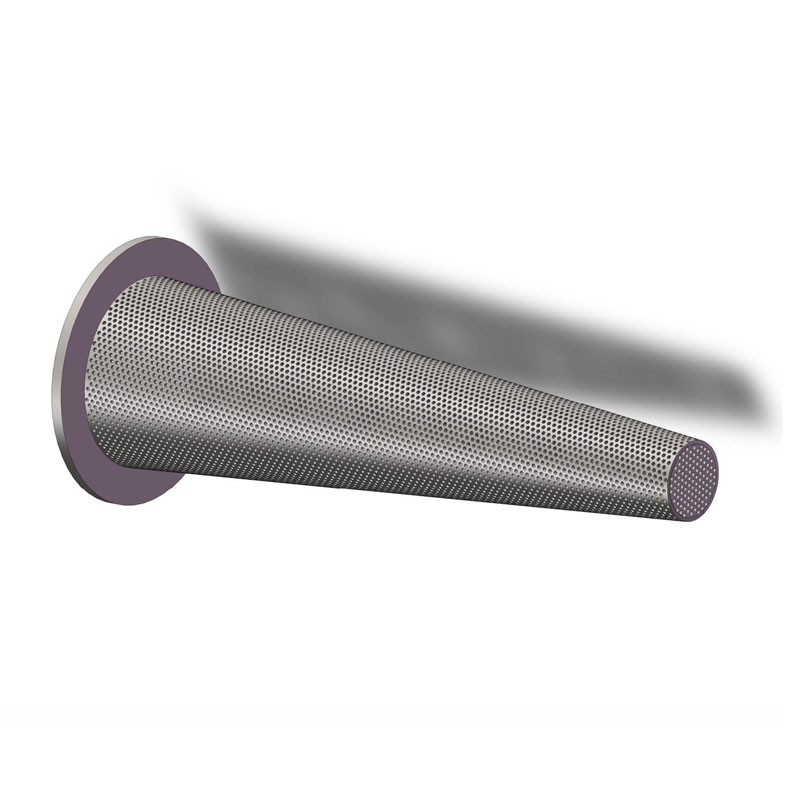

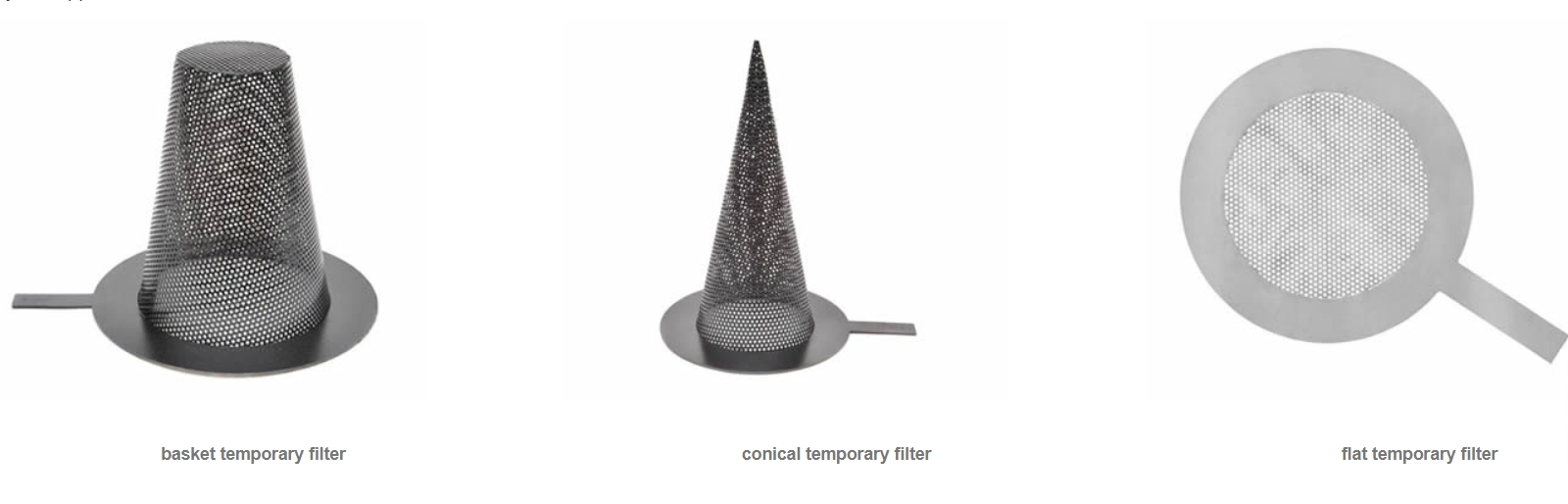

Temporary strainers offer excellent, low-cost protection for costly filtration equipment, valves, and other mechanical equipment.

Excellent for pipeline start-up or minimal solid loading.

Custom sizes, configurations, materials of construction, and other options may be available.

Product Details

Temporary strainers offer excellent, low cost protection for costly filtration equipment, valves and other mechanical equipment.

Excellent for pipeline start-up or minimal solid loading.

Custom sizes, configurations, materials of construction and other options may be available.

The materials of construction of a strainer should be compatible with the fluid. Most commonly used materials of construction are :

- Stainless Steel: 304, 306 ,etc.

- Monel Metal

Also available other materials may also be available; please contact YUBO.

10 mesh, 20 mesh, 30 mesh, 40 mesh, 60 mesh, 80 mesh, 100 mesh.

For mesh-lined strainers, flow direction must be specified.

The available range in an open area of the strainer to the cross section of the pipe is 100% to 300%.

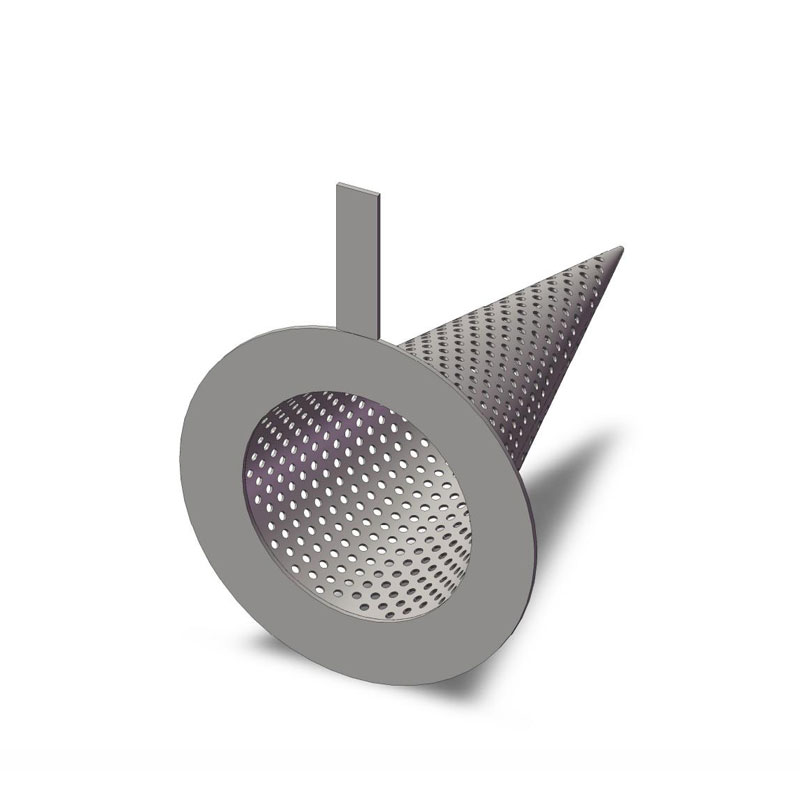

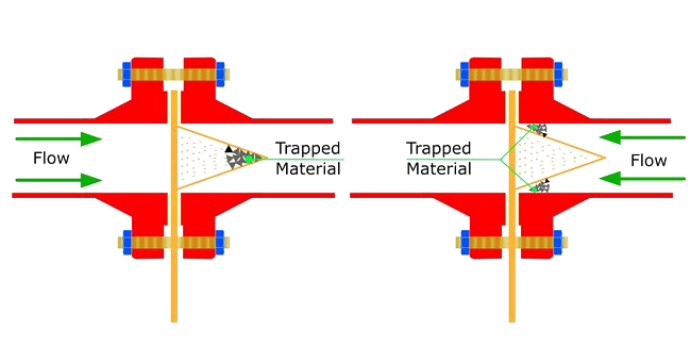

1. Installation of a conical strainer can be done in one of two different ways: cone facing upstream or cone facing downstream.

2. When the cone is downstream, debris collects inside the cone near the tip, and the cone may rip apart due to heavy strain on the tip.

3. The advantage of the cone on the downstream side is the easier removal of debris. But the mechanical strength of the cone shall be ensured.

4. When the cone is upstream, debris collects on the side of the strainer. Its advantage is that any plugging of the strainer will start in the outside and work its way in.

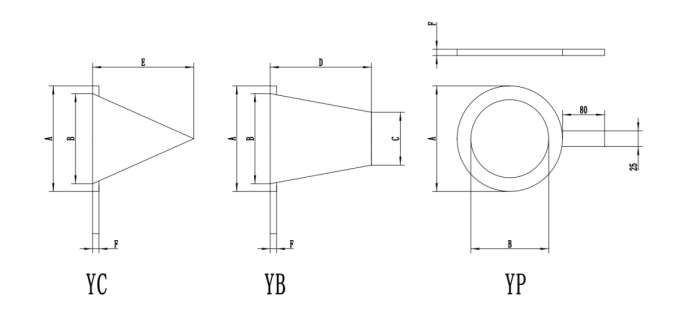

Size DN | A | B | C | D | E | F | |||||||

150/ 300# | 600# | 900# | 1500# | 150% | 200% | 300% | 150% | 200% | 300% | ||||

20 | 54 | 64 | 67 | 67 | 16 | 8 | 29 | 38 | 57 | 43 | 57 | 86 | 3 |

25 | 64 | 70 | 76 | 76 | 19 | 10 | 43 | 57 | 86 | 64 | 84 | 127 | 3 |

40 | 83 | 92 | 95 | 95 | 32 | 16 | 57 | 76 | 114 | 86 | 114 | 171 | 3 |

50 | 102 | 108 | 140 | 140 | 44 | 22 | 76 | 102 | 152 | 114 | 152 | 232 | 3 |

65 | 121 | 127 | 162 | 162 | 57 | 29 | 86 | 114 | 171 | 127 | 170 | 257 | 3 |

80 | 133 | 146 | 165 | 171 | 70 | 35 | 108 | 145 | 216 | 159 | 216 | 324 | 3 |

100 | 171 | 191 | 203 | 206 | 95 | 48 | 135 | 183 | 279 | 200 | 270 | 432 | 3 |

125 | 194 | 238 | 244 | 251 | 117 | 59 | 171 | 232 | 356 | 257 | 356 | 533 | 3 |

150 | 219 | 263 | 286 | 279 | 137 | 68 | 216 | 289 | 432 | 330 | 432 | 660 | 3 |

200 | 276 | 318 | 356 | 349 | 187 | 94 | 272 | 381 | 559 | 406 | 559 | 838 | 3 |

250 | 337 | 397 | 432 | 432 | 238 | 119 | 356 | 457 | 686 | 508 | 686 | 1016 | 3 |

300 | 406 | 454 | 495 | 517 | 279 | 140 | 432 | 559 | 838 | 610 | 838 | 1245 | 3 |

350 | 441 | 483 | 517 | 575 | 311 | 156 | 457 | 610 | 914 | 686 | 914 | 1372 | 3 |

400 | 511 | 555 | 572 | 638 | 356 | 178 | 533 | 711 | 1067 | 787 | 1041 | 1575 | 6 |

450 | 540 | 603 | 635 | 702 | 400 | 200 | 610 | 813 | 1194 | 899 | 1194 | 1803 | 6 |

500 | 597 | 676 | 695 | 753 | 445 | 222 | 686 | 889 | 1346 | 991 | 1346 | 2007 | 6 |

600 | 708 | 784 | 835 | 899 | 540 | 270 | 813 | 1067 | 1626 | 1194 | 1600 | 2413 | 6 |

Note: The flanges in this table are based on ASME.B16.5 Class150-1500#, punched plate with 3 holes and 5 spacing, and plate thickness of 1/1.5/2/3mm (depending on the situation). | |||||||||||||

Please pay more attention to the viscosity flow rate, corrosiveness, temperature, and pressure drop of your liquid before you select.

To suit your existing system without any deviation, our temporary strainer dimensions are optional in actual manufacturing. You can refer to our standard technical data to choose from, or send us your independent sizes for custom.

1. If a strainer cannot withstand high temperatures or differential pressures, it could come apart and cause damage to equipment.

2. The expected pressure drop across the strainer should not cause the downstream operating pressure to fall below the minimum required pressure of the line e.g. NPSH for a pump.

3. The perforations of the strainer should be slightly smaller than the smallest piece of debris that is expected to flow through it.

4. If the perforations are too small, a high pressure drop could develop across the strainer and cause it to fail.

1. Smooth inner face with low friction coefficient

2. Highly resistant to corrosion and abrasion and impact

3. High mechanical property and high fracture resistance

4. Low pressure drop with less energy consumption

5. Customized sizes to suit each special system requirement。

6. Support mesh/frame available for enhanced strength

Power plant

Machinery industry

Petrochemical industry

Chemical industry.

Paper & Pulp

Oil & Gas.

Mining industry.

Process industry

Proven Quality: We purchase certified raw materials for every order, and each of our temporary strainers is strictly tested by our professional quality control team before delivery.

Considerate service: We are dedicated to providing specialized pre-sale selection advice and after-sale installation guidance, and is ready to assist you 24/7.

Prompt Response: Our sales team will reply to you within 2 working hours upon receipt of your inquiry, and your call will be answered promptly if there is any chance of product details.

Competitive Price: YUBO is a production and marketing integrated company that has served hundreds of filtration projects at home and abroad, reputation for high-quality and competitive prices.