Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

In the realm of water and wastewater treatment, innovation continues to drive advancements that ensure cleaner, safer, and more sustainable outcomes. Among these innovations, Wedge Wire Screen Filters have emerged as a powerful solution, revolutionizing the way we manage and purify our precious water resources. In this article, we will explore how these filters work, their significant role in water treatment, and why they stand as a hallmark of quality and efficiency.

During coagulation, liquid aluminum sulfate (alum) and/or polymer is added to untreated (raw) water. When mixed with the water, this causes the tiny particles of dirt in the water to stick together or coagulate. Next, groups of dirt particles stick together to form larger, heavier particles called flocs which are easier to remove by settling or filtration.

As the water and the floc particles progress through the treatment process, they move into sedimentation basins where the water moves slowly, causing the heavy floc particles to settle to the bottom. Floc which collects on the bottom of the basin is called sludge and is piped to drying lagoons. In Direct Filtration, the sedimentation step is not included, and the floc is removed by filtration only.

Water flows through a filter designed to remove particles in the water. The filters are made of layers of sand and gravel, and in some cases, crushed anthracite. Filtration collects the suspended impurities in water and enhances the effectiveness of disinfection. The filters are routinely cleaned by backwashing.

Water is disinfected before it enters the distribution system to ensure that any disease-causing bacteria, viruses, and parasites are destroyed. Chlorine is used because it is a very effective disinfectant, and residual concentrations can be maintained to guard against possible biological contamination in the water distribution system.

Solids that are collected and settled out of the water by sedimentation and filtration are removed to drying lagoons.

Water fluoridation is the treatment of community water supplies for the purpose of adjusting the concentration of the free fluoride ion to the optimum level sufficient to reduce dental caries. Water is required to fluoridate water in accordance with the NSW Fluoridation of Public Water Supplies Act 1957.

Lime is added to the filtered water to adjust the pH and stabilize the naturally soft water in order to minimize corrosion in the distribution system and within customers' plumbing.

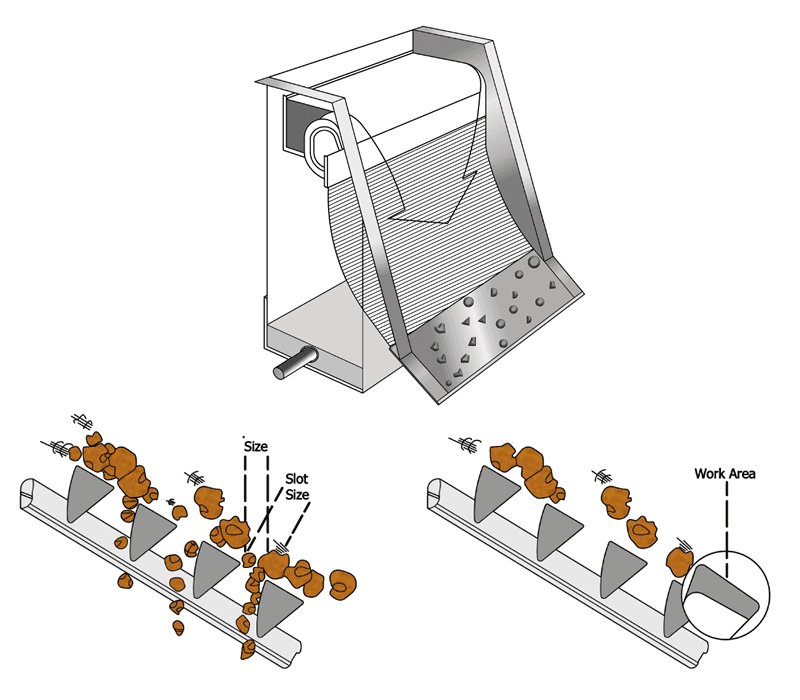

Wedge Wire Screen Filters, also known as profile wire screens, represent a breakthrough in the realm of filtration technology. These filters consist of precise wedge-shaped wires carefully arranged on a cylindrical framework. The result? An incredibly efficient filtration medium that offers exceptional mechanical strength and durability.

Filtration and Retention: As water or wastewater passes through the wedge wire screen filter, the precision-engineered wedge-shaped wires create a V-shaped slot. This slot is narrow enough to retain solids and particles while allowing water to pass through freely. The larger contaminants are effectively captured and prevented from progressing further.

Uniform Flow Distribution: The unique design of the wedge wire screen ensures an even distribution of flow across the entire surface area of the filter. This design feature prevents channeling and uneven wear, enhancing the filter's longevity and performance.

Self-Cleaning Action: One of the most significant advantages of Wedge Wire Screen Filters is their inherent self-cleaning ability. The continuous flow of water creates a shearing action that dislodges and flushes away the captured particles. This self-cleaning mechanism ensures uninterrupted filtration and minimizes the need for manual maintenance.

Unmatched Efficiency: The precise construction of wedge wire screens guarantees efficient separation of solids from liquids, leading to cleaner water and more effective wastewater treatment.

Robust Build: Wedge wire screens are engineered for durability. Their strong construction can withstand high pressures, making them suitable for a wide range of industrial applications.

Low Maintenance: The self-cleaning design reduces downtime and maintenance costs, allowing your filtration system to operate smoothly and continuously.

Customization: Wedge wire screens can be customized to fit specific filtration requirements, ensuring that your filtration needs are met accurately.

Sustainability: By effectively removing contaminants from water and wastewater streams, these filters contribute to environmental sustainability and regulatory compliance.

We are a manufacturer of Wedge Wire Screen Filters which bring expertise, innovation, and quality to the forefront. Our commitment to engineering excellence ensures that the filters meet stringent industry standards, enabling consistent and reliable filtration performance. With a track record of delivering cutting-edge solutions, we not only provide top-tier products but also offer comprehensive support, from installation to after-sales service.

Wedge Wire Screen Filters are the cornerstone of modern water and wastewater treatment. Their innovative design, self-cleaning capability, and unmatched efficiency make them an attractive choice for industries seeking high-quality filtration solutions.