Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

The evolution of reactor internals has witnessed a groundbreaking shift from traditional large outer baskets to the innovative design of individual wedge wire scallop screens.

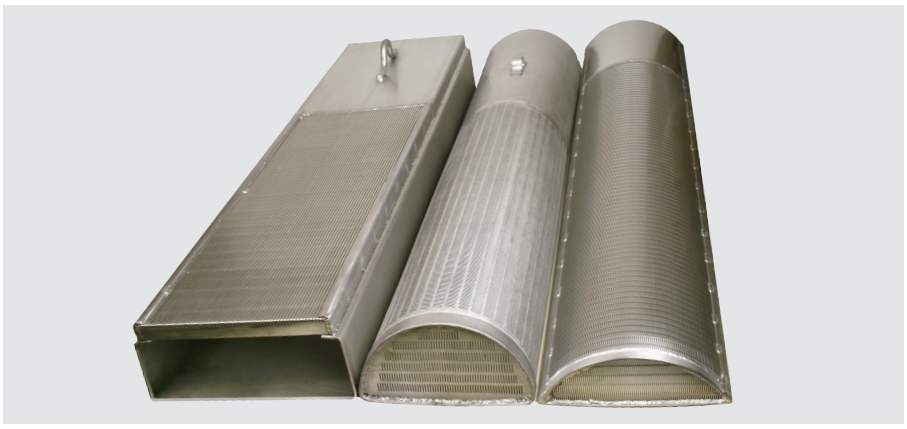

These scallop screens, predominantly tubular yet non-cylindrical, feature elongated curved surfaces, perforated or slotted to provide a partially open filtering surface. Their robust construction ensures resilience against external forces, such as those exerted by a bed of particulate material within the reactor.

An exemplary design involves arranging a multitude of scallop elements along the inner wall of the reactor vessel, forming a circular bed of catalyst between the scallops' partially open surfaces and a perforated inner screen member. This internal setup, collectively termed the internals of the reactor, orchestrates the fluid flow—wherein reactant gases or liquids traverse through the scallop openings, penetrate the catalyst bed, pass through the perforated outer surface of the inner screen, and finally exit the reactor.

The advantages of employing screen scallops in radial flow reactors are manifold. Refineries experience heightened cost-effectiveness and operational ease owing to the durability, easy installation, and simplified maintenance of these scallops, crafted from welded wires and rods to resist bending, twisting, and collapsing. Moreover, they effectively withstand extreme temperature fluctuations, virtually eliminating damage during installation and cyclic operations.

The performance enhancement is two-fold: prevention of catalyst abrasion during bed movement due to the vertical slot orientation and the high open area that directly translates into reduced pressure drop and amplified process efficiency.

These Johnson screen scallops, available in diverse sizes and materials such as 304, 316, and 316L stainless steels, cater to specific process requirements. Their wedge wire construction makes them ideal for segregating catalysts in catalytic reactions, adsorption, and treatment operations.

The unique configuration of V-wire screen scallops accentuates operational advantages. Vertical slots facilitate smooth movement of the catalyst without causing abrasions while retaining smaller-sized catalysts.

Despite the narrowness of individual slots, the cumulative total open area of V-wire scallops significantly surpasses that of single large outer baskets or perforated sheet scallops of similar dimensions. This expanded open area directly correlates to decreased pressure drop and heightened process efficiency.