Tel: +86 311 8595 5658 E-mail: admin@yuanlvfilter.com

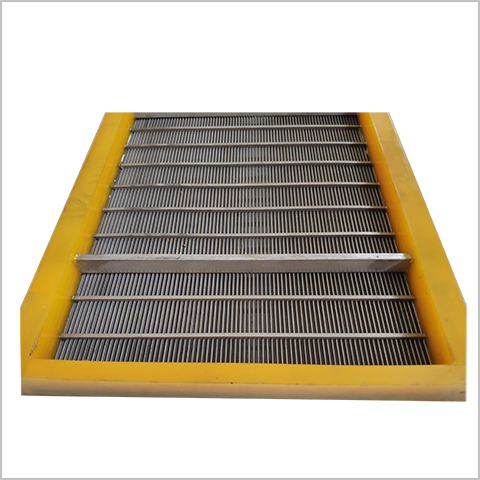

Polyurethane screen panels are essential components used in vibrating screens and screening equipment, particularly in industries such as mining, aggregate processing, and coal washing. These panels are crafted from polyurethane, a synthetic polymer known for its exceptional elasticity, durability, and resistance to abrasion.

Their superior performance in challenging environments has replaced traditional screen materials like rubber and metal.

Coal washing, also known as coal preparation or beneficiation, is a process designed to remove impurities and unwanted materials from raw coal. The objective is to enhance the quality of coal by reducing its ash and sulfur content, ultimately improving its combustion characteristics. Coal washing involves various stages, including crushing, screening, gravity separation, and flotation.

Screening plays a crucial role in separating coal particles by size, ensuring the product meets quality specifications.

Vibrating screens are widely used for this purpose due to their efficiency.

1. Raw Coal Screening: Polyurethane screen panels effectively separate oversized and undersized coal particles at the initial stage of washing, facilitating impurity removal.

2. Desliming Screens: These screens use polyurethane panels to remove fine particles and silt, enhancing coal purity.

3. Dewatering Screens: Polyurethane panels resist moisture and corrosion, crucial for removing excess water from washed coal.

4. Fine Coal Centrifuges: Used in fine coal separation based on density, benefiting from polyurethane's durability and precise screening capabilities.

Extended Service Life: Polyurethane's wear resistance ensures longer panel lifespan, reducing downtime for replacements.

Cost Efficiency: Lower maintenance costs due to durability contribute to overall operational cost savings.

Efficient Particle Separation: Flexible polyurethane panels achieve precise particle separation, meeting stringent coal quality requirements.

Moisture and Corrosion Resistance: Ideal for wet environments like dewatering processes, ensuring reliable performance over time.

1. Mining and Quarrying: Screening ores, coal, and slag to prevent material adhesion and blockages.

2. Construction Materials: Ensuring quality aggregates in concrete and asphalt production.

3. Metallurgical Industry: Screening ores and refining slag for metal extraction.

4. Chemical Industry: Solid-liquid separation, powder screening, and chemical raw material classification.

5. Food Processing: Screening flour, sugar, and starch, and grading food raw materials.

6. Environmental Engineering: Wastewater and solid waste treatment for resource recovery and environmental protection.

7. Other Industries: Pharmaceuticals, cosmetics, papermaking, ceramics, and more for various screening and separation needs.

As the coal industry continues to evolve and environmental considerations gain prominence, the use of advanced materials like polyurethane becomes increasingly important. By improving the screening process, reducing downtime, and enhancing the overall performance of coal washing plants, polyurethane screen panels contribute to sustainable and efficient coal processing, aligning with industry demands for higher-quality coal products.

We are the coal Polyurethane Screen Panels manufacturer in China, we can offer custom services for industry projects.

If you have any questions, please don't hesitate to contact us.

Previous: Coanda Screen for Water Treatment